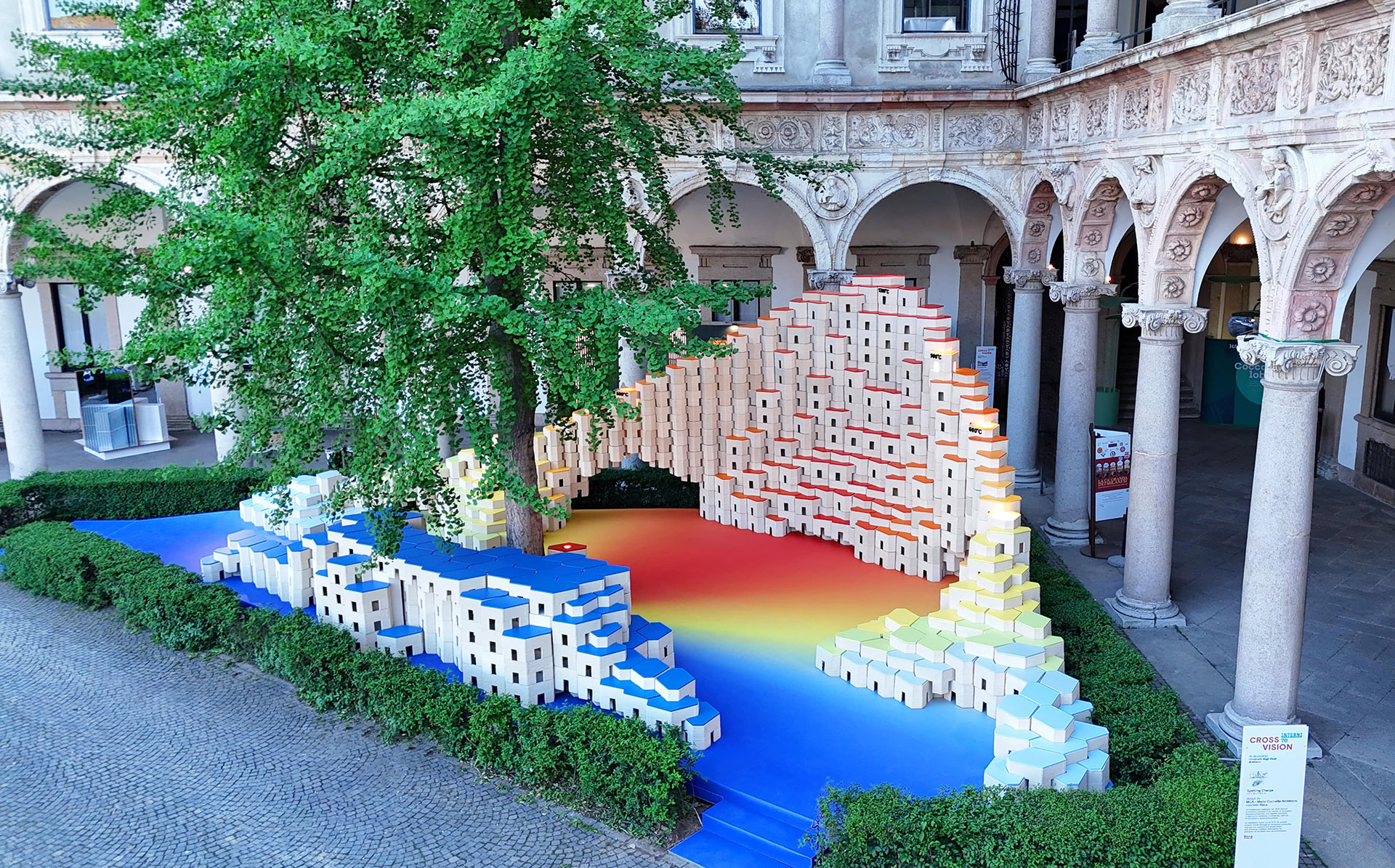

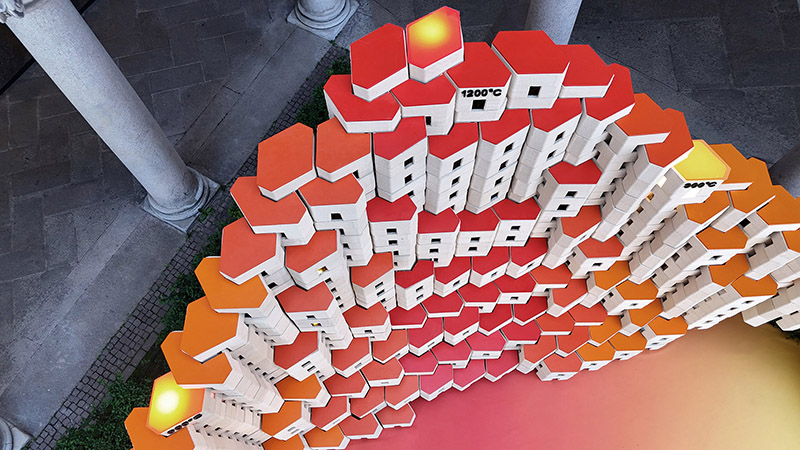

Reaching a height of 4.5 metres, a semi-circular backdrop of modular ceramic elements tells the story of the cycle of renewal at the heart of sustainability. Composed of 1,200 uniquely coloured 3D-printed ceramic blocks, the installation’s nuanced colour gradient and shape serve as visual metaphors, representing the progressive operating temperatures of the ceramic firing process. Each meticulously crafted block is embedded with details that illustrate the precise temperature required at each stage of production to ensure the highest quality ceramic products.

The installation's elegantly curved design with varying heights fits perfectly into the triangle-shaped plot and blends effortlessly into the courtyard of the University of Milan, offering a range of spatial and functional possibilities. More than just visually appealing, these versatile blocks become part of the narrative, transforming into inviting seating areas that encourage visitors to unwind, engage in conversation, and socialise in this dynamic space.

“‘Sparking Change’ underscores Roca's commitment to sustainability in a unique installation that demonstrates how knowledge, experience, and technology have led Roca to develop the greatest innovation within the sector,” explains Marc Viardot, Roca Group’s Marketing and Design Director.

Blending the physical and virtual worlds, the installation offers visitors an engaging and immersive exploration into the production process of this pioneering innovation. Using web augmented reality, visitors are invited on an interactive journey to discover the discover the benefits of Roca’s innovative electric tunnel kiln. This novel approach allows visitors to delve deeper into Roca's commitment to pushing the boundaries of innovation while embracing sustainability.

Technical Innovation and Sustainability

Reflecting Roca’s core values, the installation’s 3D printed ceramic blocks embody a delicate balance of innovation, respect for tradition and environmental responsibility. Embracing the principles of both circularity and decarbonisation, ‘Sparking Change’ demonstrates how technology and digital tools can act not only as a creative medium, but also ignite a spark for new ideas.

"Sparking Change highlights an innovative technique that respects the environment and enhances tradition; further, it is tangible evidence that technology and digital tools are no longer merely instruments for creating but also for stimulating new ideas." says Mario Cucinella, Founder & Design Director of MCA – Mario Cucinella Architects.

Each block that makes up the project is produced with a low-environmental impact process, using a combination of virgin clay and recycled ceramics from the production of bathroom components. Measuring 50x40x25cm, the design allows for a self-supporting and dry-assembled structure. This not only enhances its aesthetic appeal, but also allows for easy disassembly and paves the way for potential re-use of the blocks in future events.

Decarbonised ceramics production

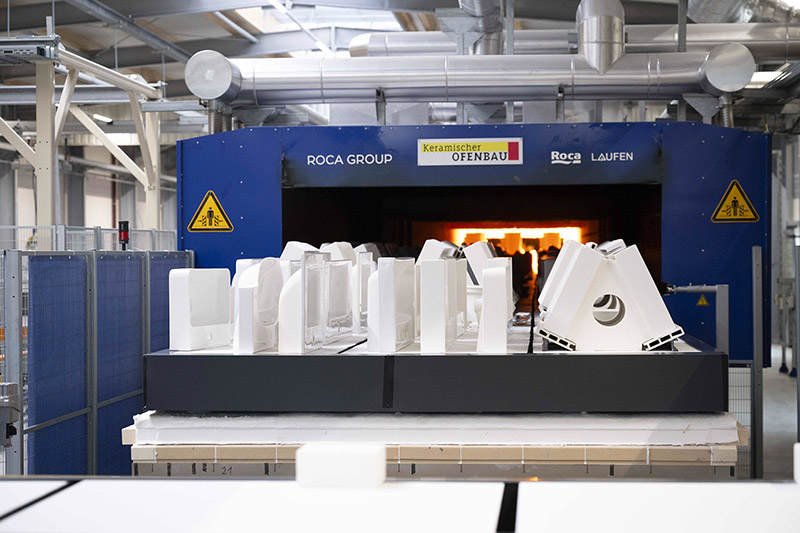

In partnership with Keramischer OFENBAU GmbH, Roca Group unveiled the world’s first electric tunnel kiln for the production of sanitaryware ceramics at its Laufen plant in Gmunden (Austria). This groundbreaking initiative has positioned Roca Group as a global leader with a net-zero sanitaryware production facility, representing a paradigm shift for the ceramics sector as a whole.

The electric tunnel kiln is a highly efficient and sustainable alternative to traditional production methods that rely on fossil fuels. The first production results of the new kiln system show great potential for the entire industry, as not only sanitaryware production can benefit from this new technology, but also other ceramic sectors such as structural and technical ceramics or tableware can benefit from this new technology. The progress made in achieving complete decarbonisation in ceramics production demonstrates its feasibility, economic viability and potential to pave the way for a sustainable future.

This milestone in a net-zero sanitaryware production facility is central to Roca Group’s decarbonisation strategy and will play a pivotal role in helping the Group achieve its target of carbon neutrality by 2045. Inching closer to this target, the Group closed 2022 with a 39% reduction in CO2 emissions from its operations compared to the 2018 baseline.

Continuing to drive decarbonisation across the entire industry requires intensive development and bold innovation. The Group is committed to supporting Keramischer OFENBAU GmbH with additional funding to further develop, implement, and market this cutting-edge technology that will shape the future of the industry.